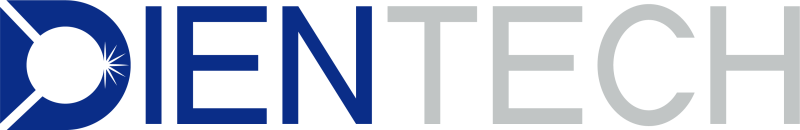

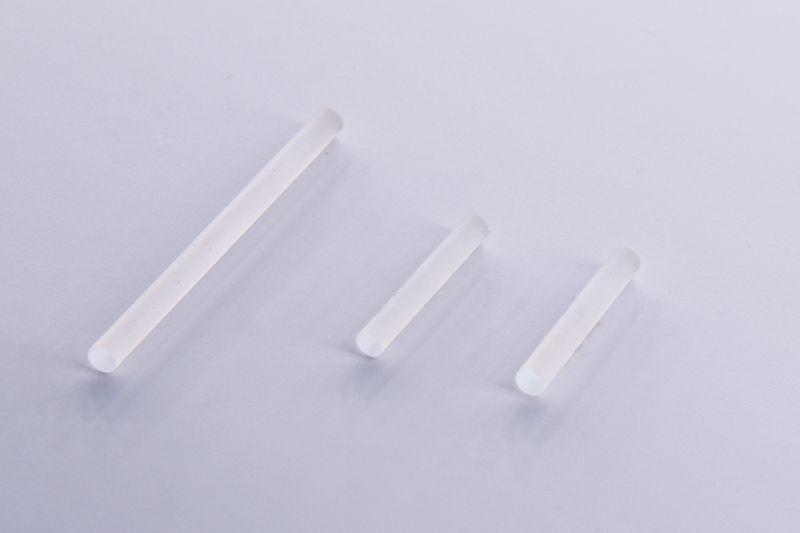

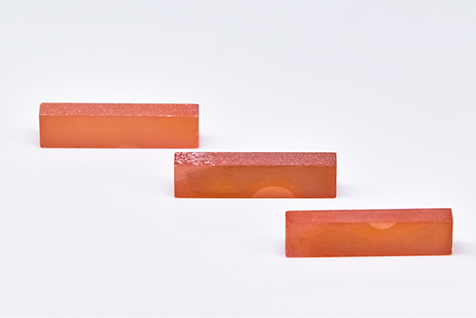

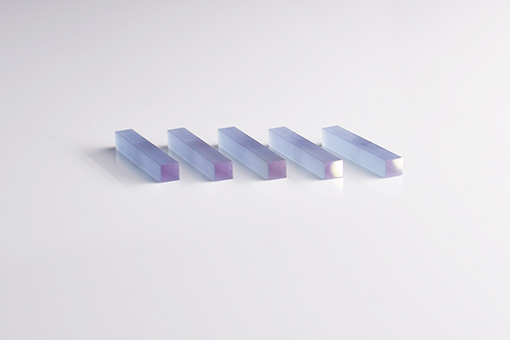

Yb:YAG Crystals

Yb:YAG is one of the most promising laser-active materials and more suitable for diode-pumping than the traditional Nd-doped systems. Compared with the commonly used Nd:YAG crsytal, Yb:YAG crystal has a much larger absorption bandwidth to reduce thermal management requirements for diode lasers, a longer upper-laser level lifetime, three to four times lower thermal loading per unit pump power. Yb:YAG crystal is expected to replace Nd:YAG crystal for high power diode-pumped lasers and other potential applications.

Yb:YAG shows great promise as a high power laser material. Several applications are being developed in the field of industrial lasers, such as metal cutting and welding. With high quality Yb:YAG now available, additional fields and applications are being explored.

Advantages of Yb:YAG Crystal:

• Very low fractional heating, less than 11%

• Very high slope efficiency

• Broad absorption bands, about 8nm@940nm

• No excited-state absorption or up-conversion

• Conveniently pumped by reliable InGaAs diodes at 940nm(or 970nm)

• High thermal conductivity and large mechanical strength

• High optical quality

Applications:

• With a wide pump band and excellent emission cross-section Yb:YAG is an ideal crystal for diode pumping.

• High Output Power 1.029 1mm

• Laser Material for Diode Pumping

• Materials Processing, Welding and Cutting

Basic Properties:

| Chemical Formula | Y3Al5O12:Yb (0.1% to 15% Yb) |

| Crystal Structure | Cubic |

| Output Wavelength | 1.029 um |

| Laser Action | 3 Level Laser |

| Emission Lifetime | 951 us |

| Refractive Index | 1.8 @ 632 nm |

| Absorption Bands | 930 nm to 945 nm |

| Pump Wavelength | 940 nm |

| Absorption band about pump wavelength | 10 nm |

| Melting Point | 1970°C |

| Density | 4.56 g/cm3 |

| Mohs Hardness | 8.5 |

| Lattice Constants | 12.01Ä |

| Thermal Expansion Coefficient | 7.8×10-6 /K , [111], 0-250°C |

| Thermal Conductivity | 7.8×10-6 /K , [111], 0-250°C |

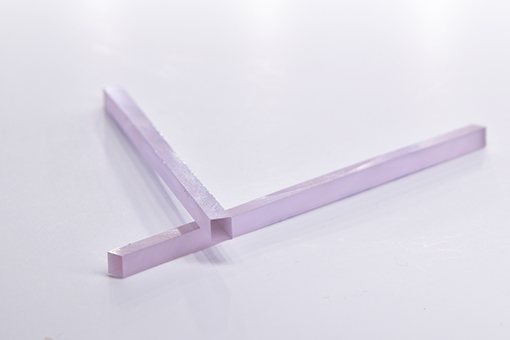

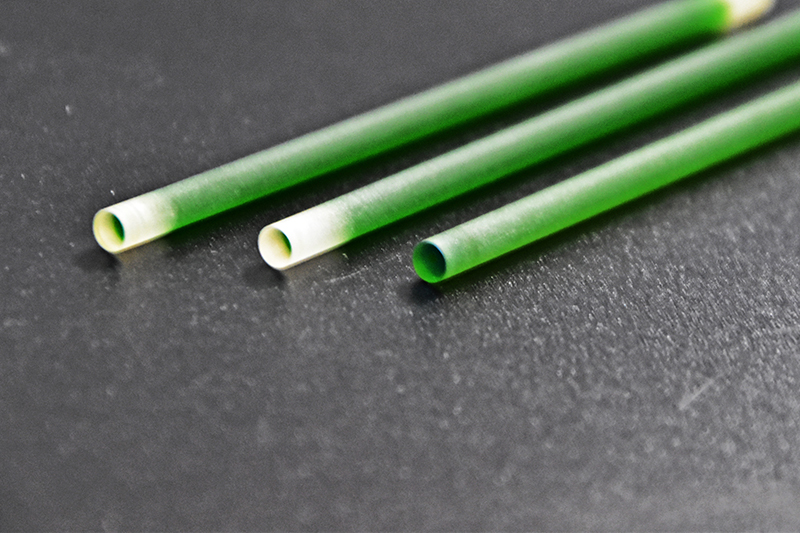

Technical Parameters:

| Orientation | within 5° |

| Diameter | 3 mm to 10mm |

| Diameter Tolerance | +0.0 mm/- 0.05 mm |

| Length | 30 mm to 150 mm |

| Length Tolerance | ± 0.75 mm |

| Perpendicularity | 5 arc-minutes |

| Parallelism | 10 arc-seconds |

| Flatness | 0.1 wave maximum |

| Surface Finish | 20-10 |

| Barrel Finish | 400 grit |

| End Face Bevel: | 0.075 mm to 0.12 mm at 45° angle |

| Chips | No chips allowed on end face of rod; chip having maximum length of 0.3 mm permitted to lie in the area of bevel and barrel surfaces. |

| Clear aperture | Central 95% |

| Coatings | Standard coating is AR at 1.029 um with R<0.25% each face. Other coatings available. |

Products categories

-

Phone

Phone

-

Email

Email

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Top