-

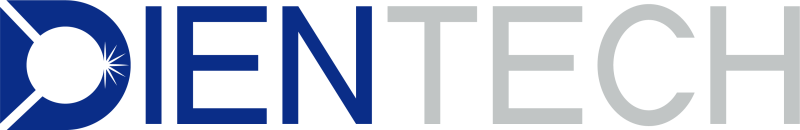

Zero-Order Waveplates

The zero order waveplate is designed to give a retardance of zero full waves, plus the desired fraction.Zero order waveplate shows better performance than multiple order wavepalte.It has broad bandwidth and a lower sensitivity to temperature and wavelength changes.It should be considered for more critical applications.

-

Achromatic Waveplates

Achromatic waveplates by using two pieces of plates.It is similar to Zero-order waveplate except that the two plates are made from different materials,such as crystal quartz and magnesium fluoride. Since the dispersion of the birefringence can be different for the two materials,it is possible to specify the retardation values at a wavelength range.

-

Dual Wavelength Waveplates

Dual wavelength waveplate is widely used on Third Harmonic Generation (THG) system. When you need a NLO crystal for type II SHG (o+e→e), and a NLO crystal for type II THG (o+e→e), the out put polarization from SHG can not be used for THG. So you must turn the polarization to get two perpendicular polarization for type II THG. Dual wavelength waveplate works like a polarizing rotator, it can rotate the polarization of one beam and remain another beam’s polarization.

-

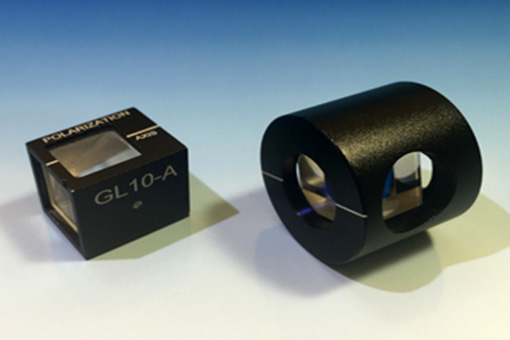

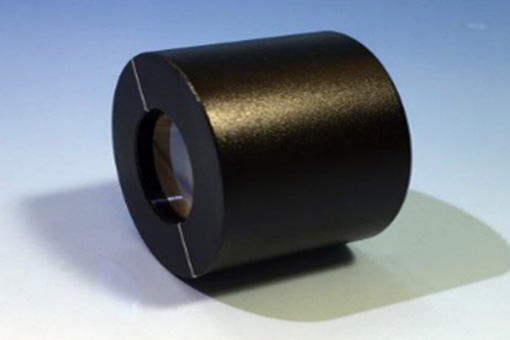

Glan Laser Polarizer

Glan Laser prism polarizer is made of two same birefringent material prisms that are assembled with an air space. The polarizer is a modification of the Glan Taylor type and is designed to have less reflection loss at the prism junction. The polarizer with two escape windows allow the rejected beam to escape out of the polarizer, which makes it more desirable for high energy lasers. The surface quality of these faces is relatively poor as compared to that of entrance and exit faces. No scratch dig surface quality specifications are assigned to these faces.

-

Glan Taylor Polarizer

Glan Taylor polarizer is made of two same birefringent material prisms that are assembled with an air space.Its length to aperture ratio which is less than 1.0 makes it a relatively thin polarizer.The polarizer with no side escape windows is suitable for low to medium power application where the side rejected beams are not required .The angular field of different materials of polarizers is listed below for comparison.

-

Glan Thompson Polarizer

Glan-Thompson polarizers consist of two cemented prisms made from the highest optical grade of calcite or a-BBO crystal. Unpolarized light enters the polarizer and is split at the interface between the two crystals. The ordinary rays are reflected at each interface, causing them to be scattered and partially absorbed by the polarizer housing. The extraordinary rays pass straight through the polarizer, providing a polarized output.

-

Phone

Phone

-

Email

Email

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Top