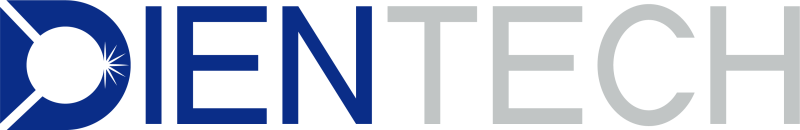

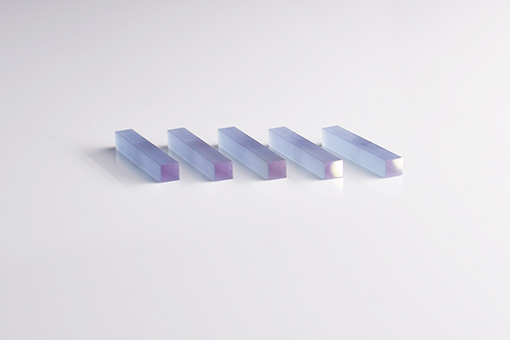

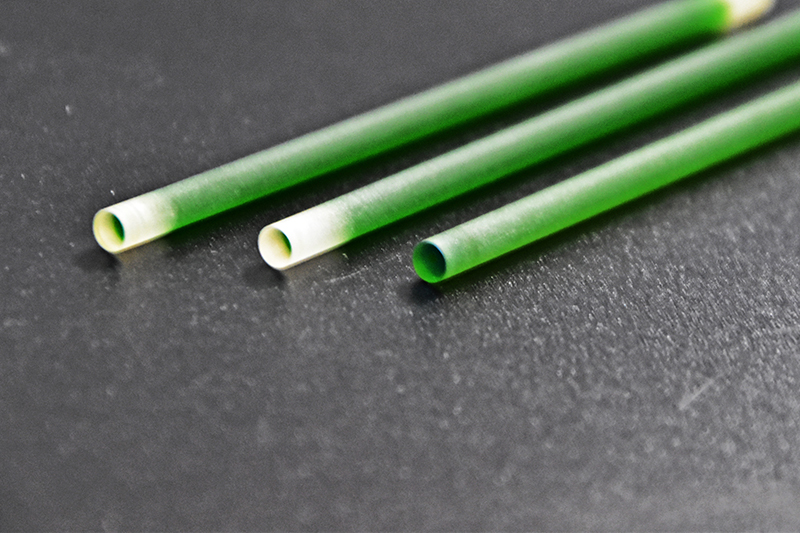

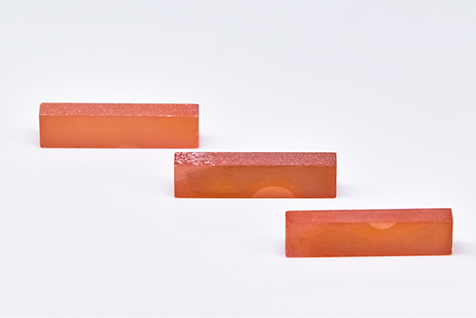

Nd: YAG Crystals

Nd: YAG crystal rod is used in Laser marking machine and other laser equipment.

It is the only solid substances that can work continuously at room temperature, and is the most excellent performance laser crystal.

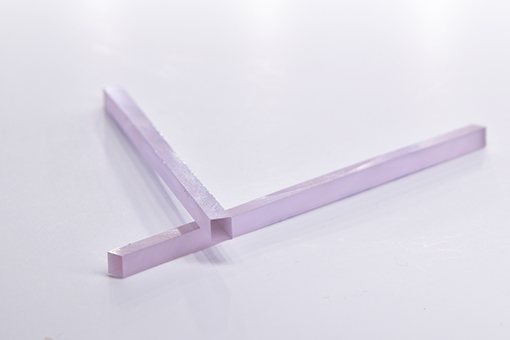

Also, the YAG (yttrium aluminium garnet) laser can be doped with chromium and neodymium in order to enhance the absorption characteristics of the laser.The Nd,Cr:YAG laser is a solid state laser.Chromium ion(Cr3+) has a broad absorption band; it absorbs the energy and transfers it to the neodymium ions(Nd3+) by way of dipole-dipole interactions.Wavelength of 1064nm is emitted by this laser.

The laser action of Nd:YAG laser was first demonstrated at the Bell Laboratories in the year of 1964.The Nd,Cr:YAG laser is pumped by a solar radiation.By doping with chromium,the energy absorption capacity of the laser is enhanced and ultra short pulses are emitted.

Basic Properties of Nd:YAG

| Product name | Nd:YAG |

| Chemical Formula | Y3Al5O12 |

| Crystal structure | Cubic |

| Lattice constant | 12.01Å |

| Melting point | 1970°C |

| orientation | [111] or [100],within 5° |

| Density | 4.5g/cm3 |

| Reflective Index | 1.82 |

| Thermal Expansion Coefficient | 7.8×10-6 /K |

| Thermal Conductivity (W/m/K) | 14, 20°C / 10.5, 100°C |

| Mohs hardness | 8.5 |

| Radiative Lifetime | 550 us |

| Spontaneous Fluorescence | 230 us |

| Linewidth | 0.6 nm |

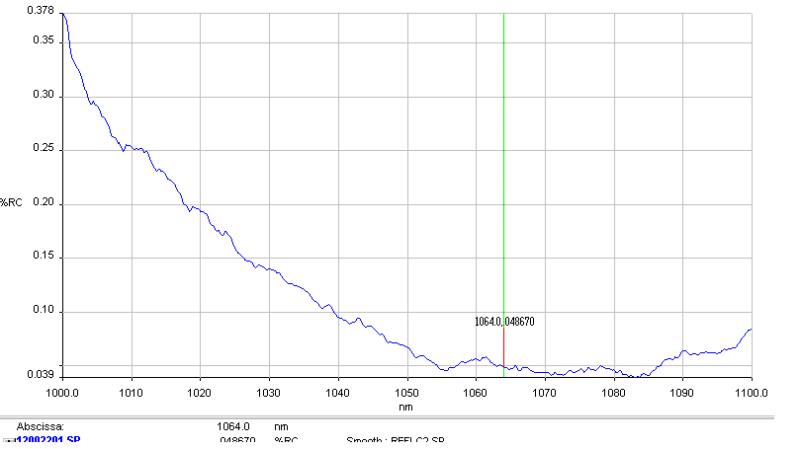

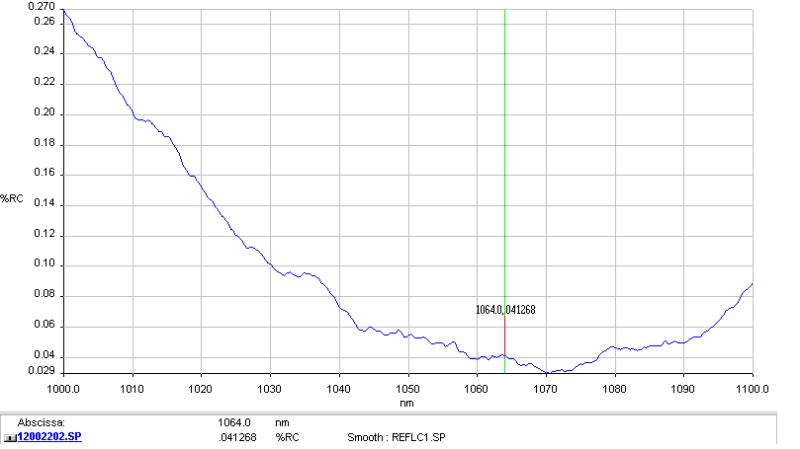

| Loss Coefficient | 0.003 cm-1 @ 1064nm |

Basic Properties of Nd,Cr:YAG

| Laser type | Solid |

| Pump source Solar Radiation | Solar Radiation |

| Operating wavelength 1.064 µm | 1.064 µm |

| Chemical formula Nd3+:Cr3+:Y3Al5O12 | Nd3+:Cr3+:Y3Al5O12 |

| Crystal structure Cubic | Cubic |

| Melting point 1970°C | 1970°C |

| Hardness 8-8.5 | 8-8.5 |

| Thermal conductivity 10-14 W/mK | 10-14 W/mK |

| Young’s modulus 280 GPa | 280 GPa |

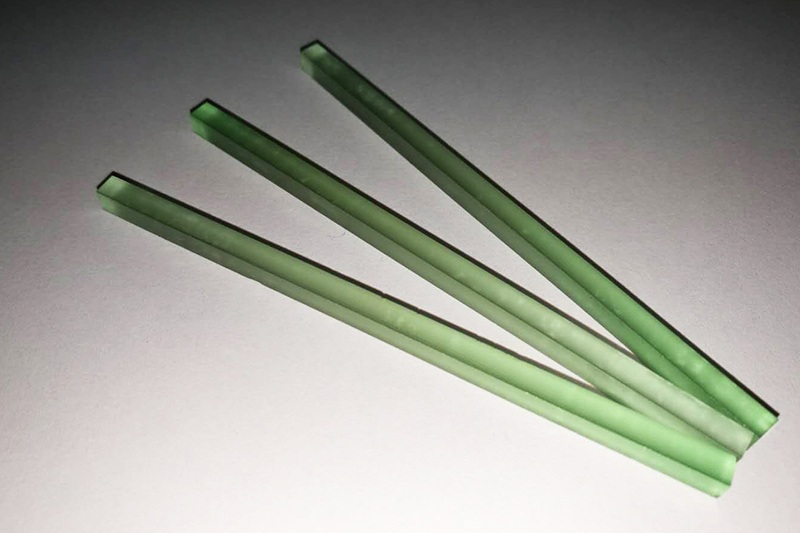

Technical Parameters

| Dimension | maximum diameter of dia.40mm |

| Nd Dopant Level | 0~2.0atm% |

| Diameter Tolerance | ±0.05mm |

| Length Tolerance | ±0.5mm |

| Perpendicularity | <5′ |

| Parallelism | <10″ |

| Wavefront distortion | L/8 |

| Flatness | λ/10 |

| Surface quality | 10/ 5 @ MIL-O-13830A |

| Coatings | HR-Coating: R>99.8%@1064nm and R<5% @808nm |

| AR-Coating (Single layer MgF2):R<0.25% per surface (@1064nm) | |

| Other HR coatings | Such as HR @1064/532 nm, HR @946 nm, HR @1319 nm and other wavelengths are also available |

| Damage Threshold | >500MW/cm2 |

Products categories

-

Phone

Phone

-

Email

Email

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Top