China Factory for Xenon Lamp - ZnSe Windows – Dien

China Factory for Xenon Lamp - ZnSe Windows – Dien Detail:

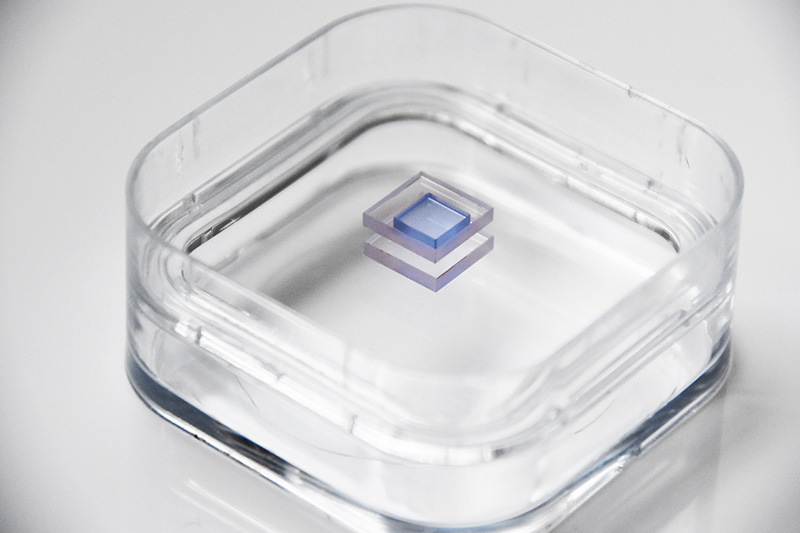

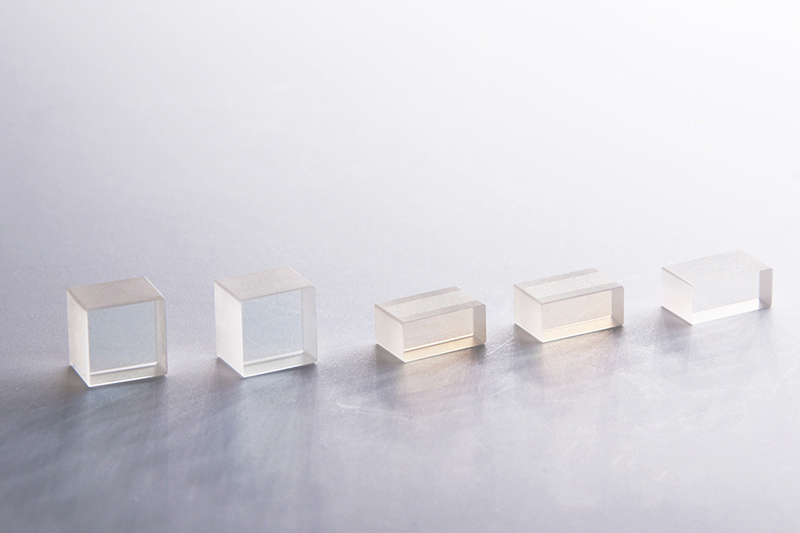

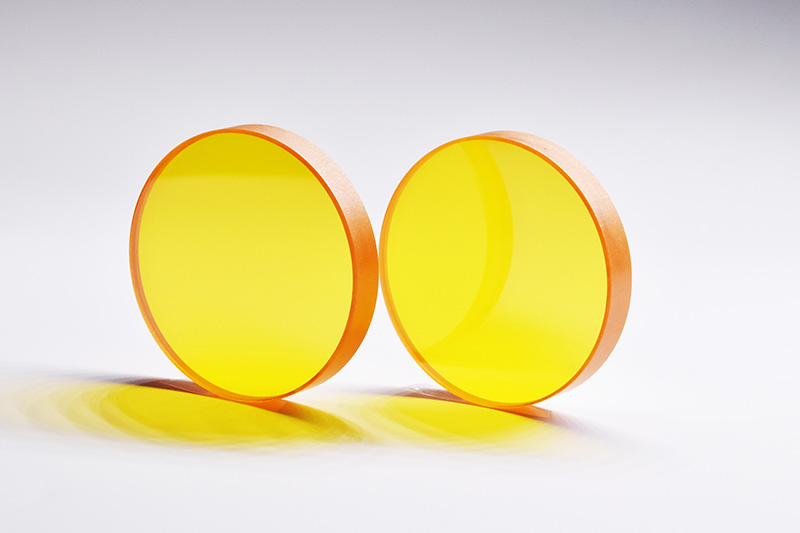

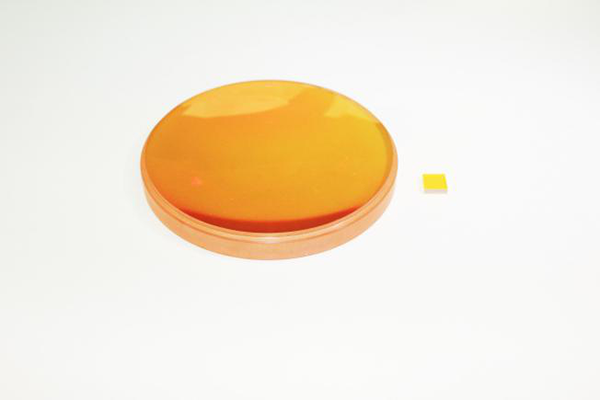

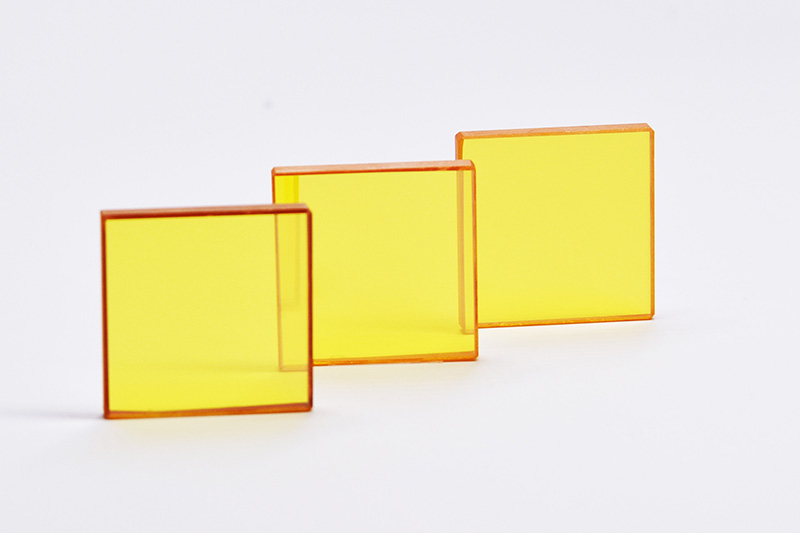

ZnSe is a kind of yellow and transparent mulit-cystal material, the size of crystalline particle is about 70um, transmitting range from 0.6-21um is an excellent choice for a variety of IR applications including high power CO2 laser systems.

Zinc Selenide has low IR absorption. This is advantageous for thermal imaging, where temperatures of remote objects are ascertained via their blackbody radiation spectrum. Long wavelength transparency is crucial for imaging room temperature objects, which radiate at peak wavelength of approximately 10 μm with very low intensity.

ZnSe has a high index of refraction which requires an anti-reflection coating to achieve high transmission. Our broadband AR coating is optimized for 3 μm to 12 μm.

Znse material made by chemical vapor deposition(CVD) basically doesn’t exist impurity absorption, scattering damage is very low. Because of a very low light absorption for 10.6um wavelength, so ZnSe is the first choice material for making optical elements of high-power Co2 laser system. Furthermore ZnSe is also a kind of common used material for different optical system in whole transmitting waveband.

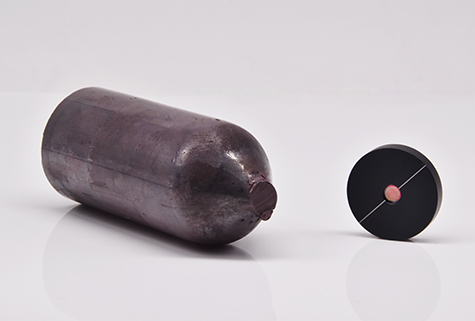

Zinc Selenide is produced by synthesis from Zinc vapour and H2Se gas, forming as sheets on Graphite susceptors. Zinc Selenide is microcrystalline in structure, the grain size being controlled to produce maximum strength. Single crystal ZnSe is available, but is not common but has been reported as having lower absorption and thus more effective for CO2 optics.

Zinc Selenide oxidizes significantly at 300°C, exhibits plastic deformation at about 500°C and dissociates about 700°C. For safety, Zinc Selenide windows should not be used above 250°C in normal atmosphere.

Applications:

• Ideal for high power CO2 laser applications

• 3 to 12 μm broadband IR antireflection coating

• Soft material not recommended for harsh environments

• High and low power laser,

• laser system,

• medical science,

• astronomy and IR night vision.

Features:

• Low scattering damage.

• Extremely low IR absorption

• Highly resistant to thermal shock

• Low dispersion and low absorption coefficient

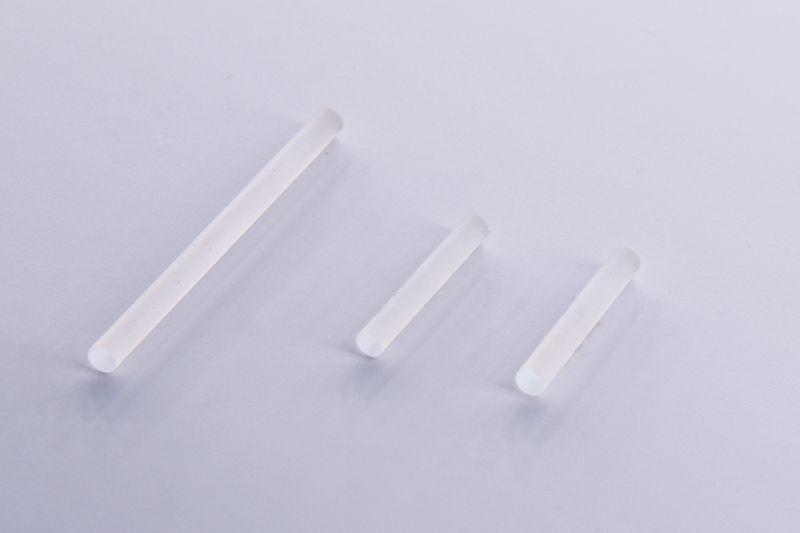

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for China Factory for Xenon Lamp - ZnSe Windows – Dien , The product will supply to all over the world, such as: Guatemala, Plymouth, San Francisco, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Products categories

-

Phone

Phone

-

Email

Email

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Top